A Leader in the Design and Manufacture of High Density Microminiature Connectors Since 1974

Your Total Microminiature Connection

Our dedication to product quality, on time delivery and competitive pricing is your assurance of satisfaction.

ITAR Registered | UL Approved | MIL DTL-83513 | RoHS

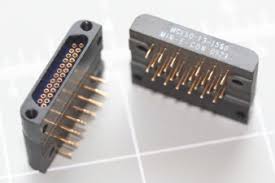

Micro-D | Mil 83513

Based off the MIL-DTL-83531 but Highly Upgraded

Used Widely in the Down-Hole Industry for Decades

Available in 9, 15, 21, 25, 31, 37, 51, 60 and 100 Contacts

Right Angle and Vertical Mount with PC Tails

Wire to Wire and Wire to Board Configurations

Interfacial Seal

Commercial Product Temperature Range -55°C to 125°C

Rated at 3A, 600VAC Max per Contact at Ambient

Min-E-Con Designation | MNR (200°C, Nickel Shell) or MBR (200°C, Black Anodized Shell)

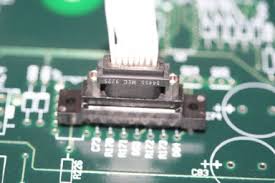

Micro-D | Low Profile

Available in Plastic or Machined Aluminum Shell

The MEC low profile is also known as the Orginal D or Small Connector

The Low Profile Version has a Smaller Height Dimension than the Traditional Micro-D

Min-E-Con Designation – DSMR (Metal Shell) & DSR (Plastic Shell)

Does not Mate with Standard Micro-D’s

Micro-D | Low Profile with Chamfered Edge

Most Compact Micro-D Package

Black Anodized Shell

Very Low Profile

Designed to Fit in Circular Tool Housings

Min-E-Con Designation – DNBR

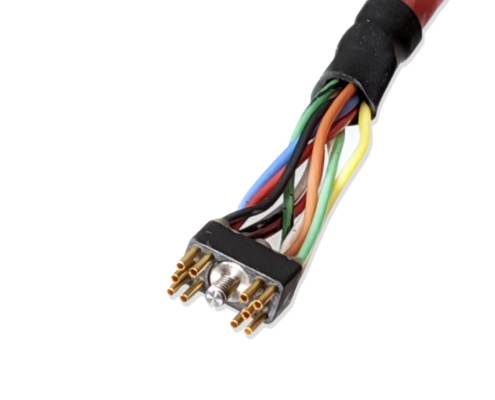

Micro-D | Hybrid Power & Signal

Utilizes Traditional Micro-D Contacts for Signal & Larger 16AWG Contacts for Power

Power Contact is rated at 13A at Ambient Temperature

Many Configurations Possible

Simply Add Suffix /06 or /07 to Any Wired Code to get High Temp Sealing

i.e. MBR15P6E518.0/07

Micro-D | Non-Magnetic

Plastic Shell | Black Anodized Shell | Aluminum Shell | Suffix/06 for Enhanced Sealing

Special Contacts with No Nickel Flash Between BeCu and Au Plate | Suffix/07 for Enhanced Sealing

Insulator Remains Standard PPS. Shell Remains Aluminum

Available for Any Micro-D option

Black Anodized Shell sans Nickel on Contacts | Suffix Code/07 for Enhanced Sealing

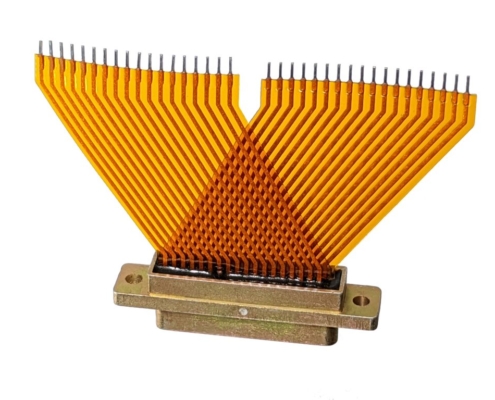

Micro-D To Flex Ciruit

Min-E-Con can Terminate most Flex Circuit Designs into Connectors

Flex Circuits Offer many Advantages Including Space Savings and Routing Options Superior to Traditional Wiring

Min-E-Con will Work with Your Approved Flex Circuit Manufacturer, or their Local Supplier to Provide a Terminated Final Product

“Sculptured Flex” Terminations are Ideal for Terminating to our Micro-D

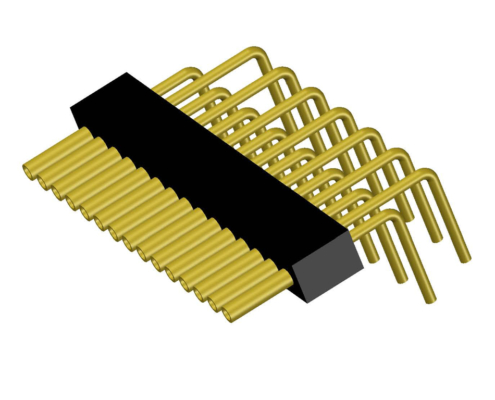

Strip Connector

Modular | Highly Configurable | Cost Effective | Shorter Lead Time

Stackable

Utilizes same High-Rel Contacts as the Micro-D 3A/600V

200°C

Guide Pins | Jackscrews | Board Mounting Holes

J Series

Space Saving Design

Ryton | PPS Body

Polyester Body 125°C

3A/600V

Center Jackscrews

Wire to Wire | Wire to Board | PC Tails

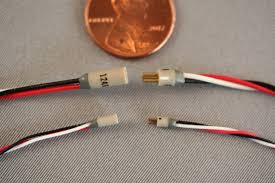

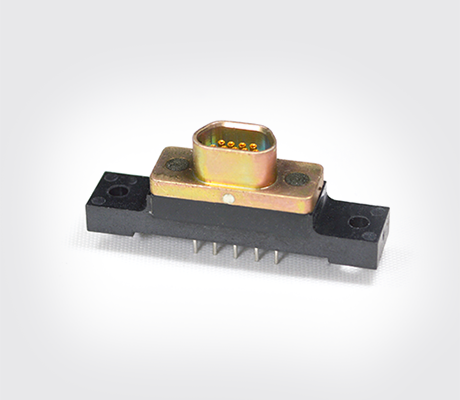

Nano

Smallest Connector Available

1/5th the Size of Micro-D

1A/250V | 200°C

NMR1 and NMR2 Options Available

Body is Machined out of Stainless Stee

Wire to Wire | Wire to Board | Right Angle PC Mount

Peek Flex Micro & Nano

Available in Any Contact Number

Available in Any Contact Shape

200°C

Body is Machined out of Peek

Guide Pins | Jackscrews | PC Tail | Hermaphroditic | Alignment Marks

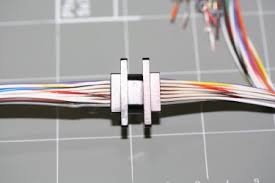

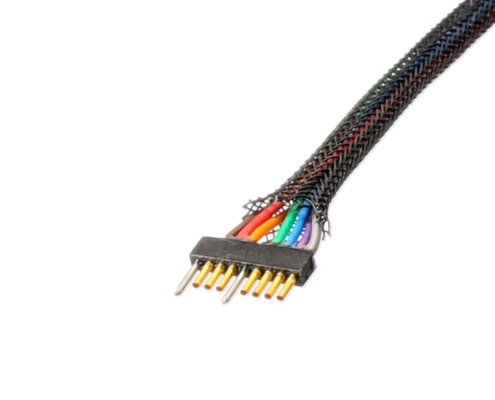

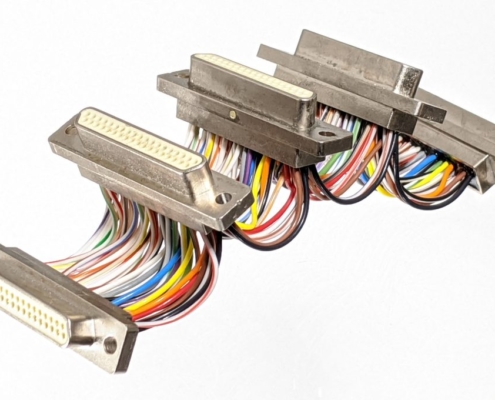

Wire Harness and Customizations

MEC Harnesses Do Not have Splices

100% Quality Tested

Can be Tape Wrapped, Sleeved, Labeled, Lacing Cord to Customer Specifications

Toroids | PC Board

Harnesses can incorporate other manufacturers connectors